Sockets made in China VS. Sockets made in Taiwan

At times when we meet our potential customers at our exhibition or through e-mail, a common questions they ask

"why are your socket price 20-30% higher than China? "

It's no surprice that buyers try to negotiate for a better price. However, there is a difference between sockets made in China and Taiwan.

Cheaper priced sockets that are made in China are usually made of low quality materials and low production standards.

Our Taiwan made sockets are made of high quality, long lasting materials with very high standards.

If your target market are those people occasionally use sockets for DIY purpose, or DIYer only use for twice a year then throw away, which price matters the most, then we recommend purchasing the lower quality sockets from China.

However, if your target market are professional workers who work in industrial settings like Auto repair, consturction companies, Engineering firms and other professional fields where quality and safety are top priority, then cearly

ARES IS THE RIGHT CHOICE FOR YOU.

Our Taiwan made hand socket wrench sets are recognized by the international hardware community as being extremly durable and of high quality. Here's the story we'd like to share with you.

Last year a potential customer sent us a sample of 1/2"drive 24PC socket set manufactured in China.

He had asked us if we were able to manufacture the same set but at lower price. We decided to test the socket set in our own laboratory,

The results showed that the sockets were of poor quality and they are not made to last.

We share our findings with our customers:

1. the metal case and tray are too thin.

2. the materials are low grade.

3. the sockets were not well processed.

4. surface are not smooth.

5. no ball hole inside the drive hole for the ratchet handle.

We then thanked hime for considering us. However, we were not willing to compromise on quality of our tools, even though he was a global suppier, we politely refused to manufacture his brand tools.

A vedio can say more words than pictures.

A simple comparison of China cheap socket set vs. Taiwan well made socket set from ARES.

1. The metal case and tray are thin.

♦ If you were to accidentally drop the case, it will be easily dented and damaged. The internal tray will be damaged as well and not hold the sockets securely in place.

♦ The tray is only about 0.4mm thick, Our tray is approximately 1.0 mm thick to ensure durability, and protection of our sockets and ratchets..

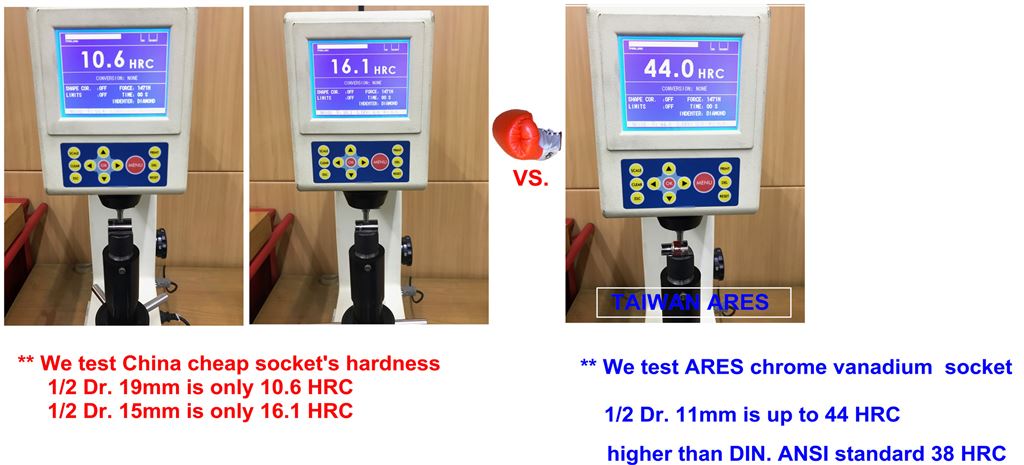

2. Results of Hardness test. Sockets should be either hardened and tempered.

2. Results of Hardness test. Sockets should be either hardened and tempered.

♦ The first thing need to know is the material very important. Material is the base. It's important for sockets to be made of strong materials so they don't break when you apply torque to them. We usually do a Rockwell C Hardness test to see how well the material can withstand force and deformation. If the material isn't hard enough, the shape will be altered and no longer correctly fit on to the fastener head.

♦ Based on our findings, the material used in making the made in China socket set is carbon steel, which hasn't been heat treated enough. As a result the tools will easily crack or fracture.

3.. Roughly lathed, no polishing and vibration

♦ the socket is only roughly lathed outside the nut end and drive end. they don't lathe the ball hole inside the drive end.

As a result, the sockets will not securely attach to the ratchet's head firmly when used.

♦ Omitting polishing and vibration will result in poor finish where lathing track are visible.

♦ Our SOP has 6 or 7 lathing processes, but the made in China set seems to have only 2 lathing process to save time and costs.

so when you touch both ends' circle area, it is a little bit sharpe, not as round and smooth as ARES'.

ARES' are smooth without any rough edges.

4. Electroplating not done properly,

4. Electroplating not done properly,

♦ You can see some minor rusting spots inside the socket, which means the eletroplating wasn't don'e properly, as a result the sockets are prone to corrosion.

♦ There are many reasons that cause socket rusting. It could be the wrong chemical fomula, insufficient nickle layering, improper hanging for plating or impurities in the water. Another factor could be long term exposure to humid weather.

5. Compare cheap ratchet with ARES' to see how is the mechanism.

6. A simple comparison of socket, the left one is cheap socket, the right one is a ARES made socket

5. Compare cheap ratchet with ARES' to see how is the mechanism.

6. A simple comparison of socket, the left one is cheap socket, the right one is a ARES made socket

Disclaimer: not all made in China socket sets are of bad quality, however, it's important to be able to distinguish between good and bad quality socket sets.